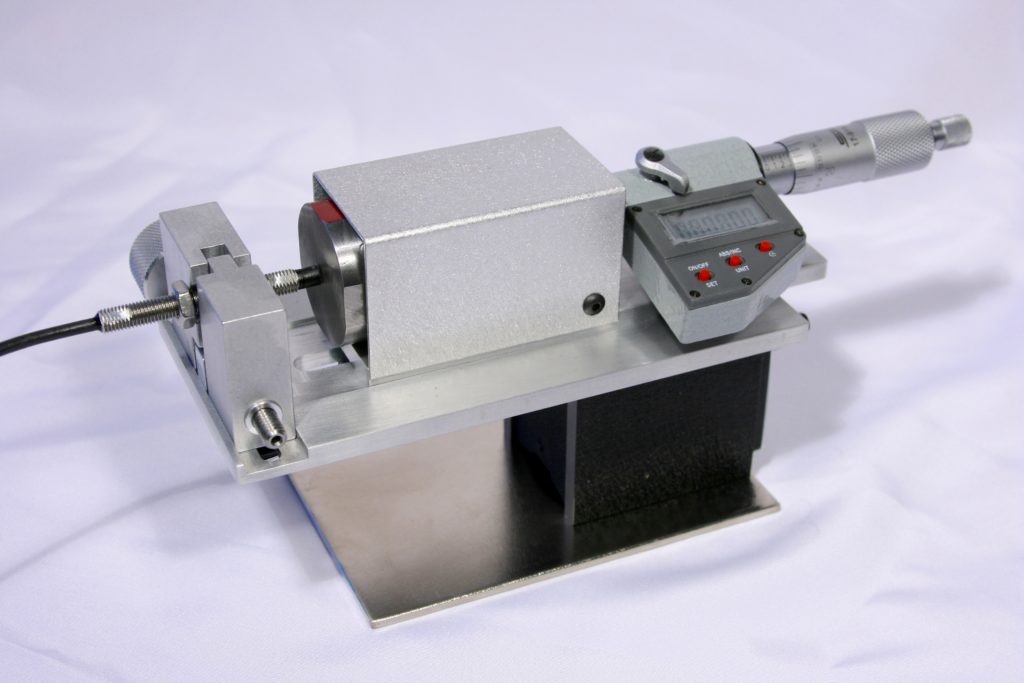

The Model 6214-UPSC offers precision calibration measurements never before possible because:

By mounting our target material on linear bearings rather than on the shaft of a micrometer, we eliminate all possibilities of the test process being affected by either ELECTRICAL or MECHNICAL RUNOUT inherent in the target material affecting the read-outs. For more information about Electrical and Mechanical Runout, go to the NEWS section of our web site.

Sales Price: $970

User Advantages

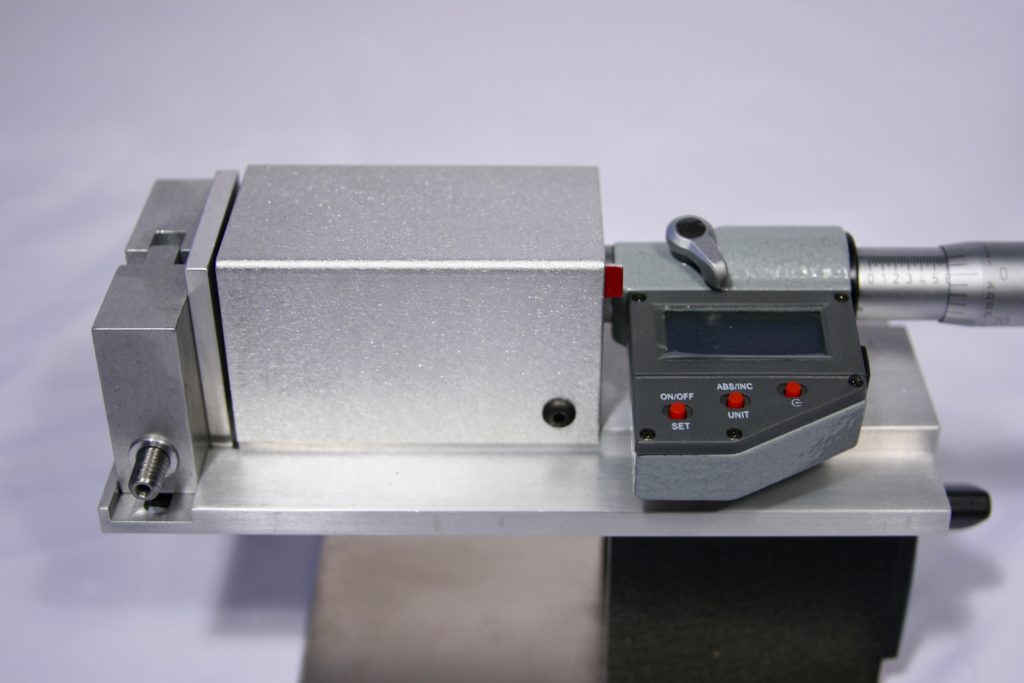

- Inch or Metric display allows use in all countries.

- The universal probe grips hold Proximity Probes from .197″ to .750″ diameters (5 mm to 19.05 mm).

- Target material is 4140 AISI steel. 1.5″ (38mm) in diameter. Contact us for other available materials.

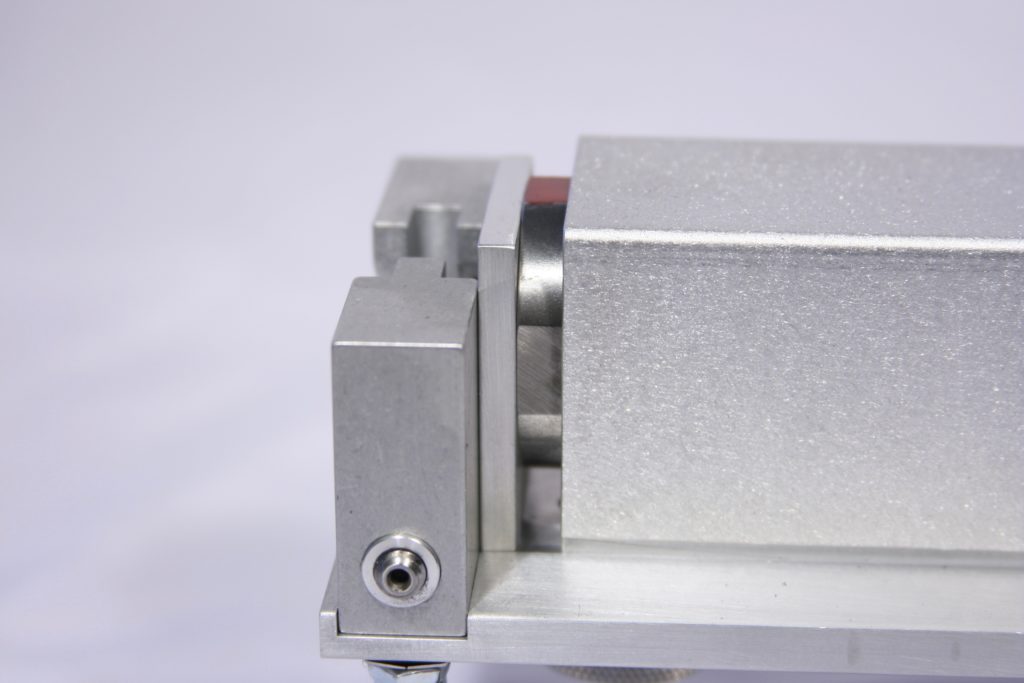

- Our Static Calibrator uses same type probe grippers as our Dynamic Calibrator and centers the probe relative to the Target material in both the Vertical and Horizontal direction while keeping the surface of the probe perfectly parallel to the surface of the target material throughout the entire testing process.

- Included with the Calibration System is a STEEL PLATE that allows you to position the Static Calibrator on any non-magnetic surface.

- The distance between the Probe Grippers and the surface of the Target Material is adjustable up to 2.180” to enable you to test a wide variety of probe lengths and configurations.

Years of use under a wide variety of handling conditions have shown us that the most common cause of damage to our Calibrators occurs during handling or shipping the units between different locations. That has caused us to make the following changes/modifications:

- AN IMPACT PLATE that sits between the Probe Grippers and the Surface of the Target Material during shipping. One side of this plate has a soft felt pad that absorbs any sharp impacts to prevent same from affecting the electronics that display the highly accurate readout.

- By turning the IMPACT PLATE around it can be used as a means to check that the Target Material is still parallel to the Probe Grippers after any dropping or other impact to the Static Calibrator as shown in photo below.

- Any hard or sharp impact to the front of the Static Calibrator during shipping or handling can cause the Digital Micrometer to fail. To prevent that from occurring we have provided a means of separating the Target Material from contact with the shaft of the Micrometer when Static Calibrator is not in use. This is illustrated in the video shown in this section of the web site.

A Protective case is now provided for the Static Calibrator when purchased as a stand alone unit.

The MODEL 6214 Static Calibrator is a development of: Gilchrist-Pearson Technology Pat. Pend.